Infrastructure

Where Precision Meets Scale.

At Narayan Metal Industries, our infrastructure is the backbone of our precision-driven manufacturing. Spread across 15,000 sq. ft., our facility is designed to ensure seamless production, strict quality control, and agile turnaround times — all under one roof.

Every zone in our plant is optimized to promote collaboration, reduce waste, and enhance output quality. Backed by a skilled workforce and modern machinery, our setup is built for scalability and precision at every level.

Key Facilities Include

Design & Development Department

Equipped for 2D/3D modeling and custom component prototyping.

SPM Unit

(Special Purpose Machines)

Custom-built machines for specific high-volume operations.

Raw Material Storage

Organized inventory system for traceability and efficient usage.

CNC Machining Unit

Multi-axis precision machining for complex geometries and tight tolerances.

VMC Unit

For high-accuracy milling and advanced surface finishing.

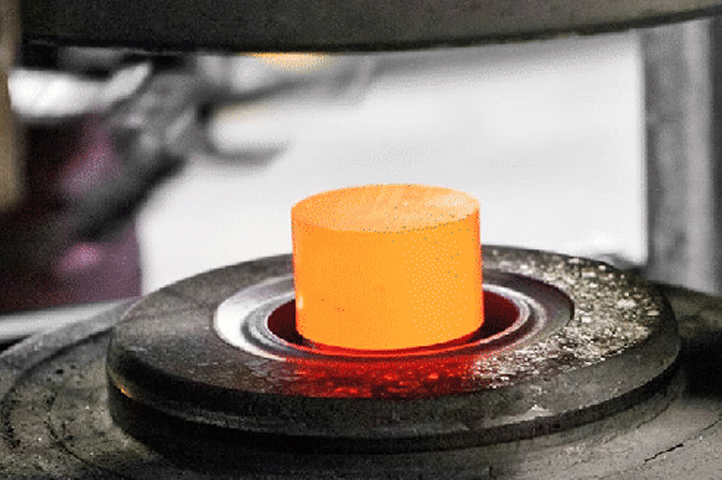

Forging Unit

Strengthening components through controlled metal deformation processes.

Assembly Unit

Integration of sub-parts and final fitment to customer specifications.

In-House Tool Room

Maintenance and development of dies, jigs, and fixtures for enhanced process reliability.

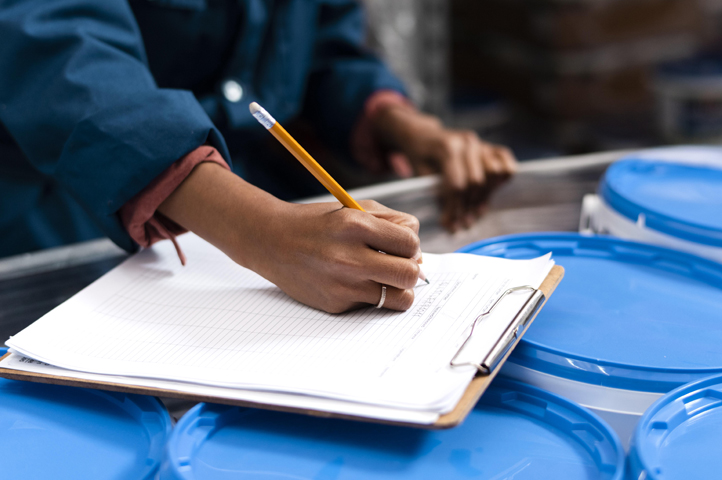

Inspection & QC Department

Stage-wise inspection and final testing to ensure zero-defect delivery.

Laser Marking Section

Permanent and precise product identification with branding capability.

Finished Goods Storage

Systematic storage for streamlined dispatch and logistics.

QC Laboratory

Equipped with advanced measuring and testing instruments for metallurgical and dimensional accuracy.