Quality

Certified Systems

We are an ISO 9001:2015 Certified company, adhering to internationally recognized quality management standards. This certification reflects our ability to consistently deliver products that meet customer and regulatory expectations.

In-Process Quality Control

To ensure reliability and repeatability, We implement Online Quality Checkpoints at every strategic stage of production.

- Each component undergoes dimensional and attribute testing

- All measuring instruments are routinely calibrated to maintain accuracy

- Quality data is documented and traceable to ensure transparency and accountability

Preventive Machine Maintenance

Our machines are the foundation of our precision. We follow a structured preventive maintenance schedule to minimize downtime, extend machine life, and ensure that every part produced meets exact specifications.

Skilled Team, Trained for Excellence

We believe quality is as much about people as it is about process.

Our team members undergo annual practical and theoretical training programs, tailored to their specific departments. This investment in learning ensures sharp skills, reduced error rates, and a shared drive for excellence.

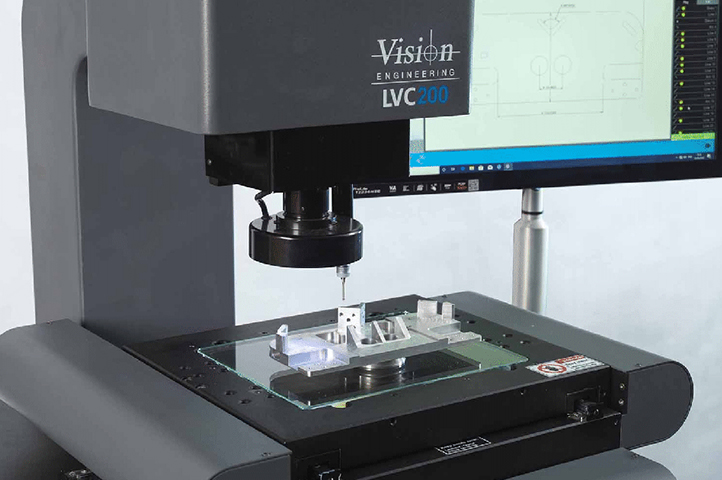

In-House QC Laboratory

We operate a fully equipped quality control laboratory to validate and verify each batch before dispatch. Our testing capabilities include:

- Material Composition Testing (Spectrometer)

- Surface Coating & Thickness Testing

- Hardness Testing

- Salt Spray Corrosion Testing

- Dimensional Accuracy (Profile Projector, Vision Measuring Machine)

- Go/No-Go Gauge Validation (Ring & Pin Gauges)

- Torque and Thread Testing